- "Top Tips for Choosing the Best Plates for Your Home

By:Admin

The new line of compostable plates is made from natural plant fibers, such as bamboo and sugarcane, and is designed to be fully biodegradable. This means that after use, the plates can be composted alongside organic waste, breaking down into nutrient-rich soil without leaving behind any harmful residues. This not only minimizes the environmental impact of disposable tableware but also offers a practical solution for reducing waste in both residential and commercial settings.

“The launch of our compostable plates is a significant milestone for Steps Plates and a testament to our ongoing commitment to sustainability,” says [Company Spokesperson]. “We believe that it is essential for businesses to actively pursue environmentally friendly alternatives, and our new line of compostable plates is a clear demonstration of our dedication to this cause. We are excited to offer consumers a more sustainable option for their dining needs, without compromising on quality or convenience.”

In addition to being compostable, the new plates are also strong and durable, making them suitable for a wide range of food service applications. Whether used for picnics, parties, or takeout meals, the compostable plates offer a reliable and eco-friendly alternative to traditional plastic and foam options. This makes them an ideal choice for individuals and businesses looking to minimize their environmental footprint without sacrificing the practicality and functionality of disposable tableware.

Furthermore, Steps Plates has ensured that the production of their compostable plates adheres to strict sustainability standards. The materials used are sourced from renewable and responsibly managed plantations, and the manufacturing process is designed to minimize energy consumption and waste generation. This ensures that the entire lifecycle of the plates is as eco-friendly as possible, from production to disposal.

As a company, Steps Plates has long been dedicated to providing sustainable and innovative tableware solutions. Their product range includes a variety of compostable and biodegradable options, including plates, bowls, and cutlery, all designed to offer a greener alternative to traditional disposable tableware. The company has also invested in research and development to continuously improve their products and explore new sustainable materials and manufacturing techniques.

In addition to their commitment to sustainability, Steps Plates is also dedicated to supporting local communities and promoting social responsibility. They actively engage in partnerships and initiatives aimed at empowering and uplifting marginalized groups, and they strive to create a positive impact beyond their business operations. This holistic approach to corporate responsibility aligns with their mission to be a force for good in the world, going beyond profit to make a meaningful difference in society and the environment.

The launch of the new compostable plates marks a significant step forward for Steps Plates as they continue to lead the way in sustainable tableware solutions. By providing consumers with a practical and environmentally friendly alternative to traditional disposable tableware, the company is demonstrating their commitment to promoting a greener and more sustainable future. With their innovative products and unwavering dedication to sustainability, Steps Plates is poised to make a lasting impact in the industry and inspire positive change on a global scale.

Company News & Blog

High-Quality Roll Forming Machine for Channel Production: A Complete Guide

The roll forming machine industry has seen a significant technological advancement with the introduction of the new U T L Channel Roll Forming Machine by a leading manufacturing company. This innovative machine has captured the attention of the industry due to its advanced features and superior performance.The U T L Channel Roll Forming Machine is designed to efficiently produce U, T, and L channel profiles with high precision and accuracy. These profiles are widely used in various industries including construction, automotive, and infrastructure. The machine is equipped with state-of-the-art technology and precision engineering to ensure the production of high-quality and consistent profiles.The roll forming machine is capable of producing U, T, and L channels of different sizes and thicknesses, making it highly versatile for various applications. It also offers a high level of automation, making it easy to operate and ensuring efficient production processes. The machine's advanced control system allows for quick setup and changeover between different profiles, improving productivity and reducing downtime.In addition to its advanced technology, the U T L Channel Roll Forming Machine is also known for its durability and reliability. The machine is built with high-quality materials and components, ensuring long-term performance and minimal maintenance requirements. This makes it an ideal investment for manufacturers looking for a reliable and cost-effective solution for their roll forming needs.The company behind the development of this innovative roll forming machine has a strong reputation in the industry for delivering high-quality and reliable manufacturing equipment. With years of experience and expertise, the company has become a trusted name in the roll forming industry, serving clients from around the world.The company is committed to providing innovative solutions to meet the evolving needs of the industry, and the introduction of the U T L Channel Roll Forming Machine is a testament to this commitment. By combining cutting-edge technology with superior engineering, the company has set a new standard for roll forming machines, offering a solution that is not only efficient and reliable but also cost-effective.The U T L Channel Roll Forming Machine has already received positive feedback from early adopters in the industry, who have praised its performance and versatility. Manufacturers have reported increased productivity and efficiency in their production processes, thanks to the advanced capabilities of the machine.In a statement, a representative from the company expressed their excitement about the launch of the U T L Channel Roll Forming Machine, emphasizing the machine's potential to revolutionize the roll forming industry. The representative highlighted the company's dedication to innovation and continuous improvement, stating that the new machine is a result of extensive research and development efforts.As the demand for high-quality roll formed products continues to grow, the U T L Channel Roll Forming Machine is poised to become a game-changer in the industry. Its advanced features, coupled with the company's reputation for excellence, position it as a top choice for manufacturers looking to enhance their production capabilities.With its advanced technology, durability, and reliability, the U T L Channel Roll Forming Machine is expected to set new benchmarks for roll forming equipment, shaping the future of the industry. As the company continues to push the boundaries of innovation, it is clear that they are committed to leading the way in providing cutting-edge solutions for manufacturers worldwide.

High-Quality Drywall U Channel and Metal Studs Steel Roll for Construction

Drywall U Channel And Metal Studs Steel Roll to Revolutionize Construction IndustryThe construction industry is constantly evolving with new technologies and materials being introduced to enhance efficiency, sustainability, and durability. In this regard, the latest innovation to make waves in the construction sector is the introduction of Drywall U Channel and Metal Studs Steel Roll, which is set to revolutionize the way buildings are constructed.With a commitment to providing high-quality and innovative building materials, [Company Name] is proud to introduce their latest product, the Drywall U Channel and Metal Studs Steel Roll. This revolutionary product is designed to simplify the construction process while ensuring superior strength and stability in building structures. Drywall U Channel is an essential component in drywall installation, providing support and stability to the walls and ceilings. It is manufactured using high-quality steel, making it incredibly durable and resistant to warping, bending, and corrosion. The U-shaped design of the channel allows for easy installation and ensures a secure fit for the drywall, resulting in a smooth and seamless finish.Metal Studs Steel Roll complements the Drywall U Channel by providing a versatile and robust framework for constructing walls and partitions. Made from premium-grade steel, the metal studs offer exceptional strength and durability, making them an ideal choice for both residential and commercial construction projects. The steel roll design allows for easy handling and installation, saving time and labor costs while ensuring a reliable and long-lasting building structure.The combination of Drywall U Channel and Metal Studs Steel Roll offers numerous benefits to construction professionals, developers, and homeowners. These innovative building materials provide unparalleled strength, stability, and consistency, ensuring that the final construction meets the highest standards of quality and safety. Additionally, the use of steel in both the U Channel and Metal Studs ensures sustainability and recyclability, making them an eco-friendly choice for construction projects.Moreover, the introduction of Drywall U Channel and Metal Studs Steel Roll is expected to streamline the construction process, saving time and labor costs. The easy installation and precise fit of these materials eliminate the need for complex and time-consuming construction techniques, allowing for faster project completion and reduced construction schedules. This not only benefits construction companies by increasing efficiency but also provides homeowners with a reliable and durable building structure in a shorter timeframe.[Company Name] takes pride in leading the way in delivering innovative and sustainable building materials to the construction industry. With a focus on quality, reliability, and customer satisfaction, the company has established a reputation for excellence in providing a wide range of construction products. The introduction of Drywall U Channel and Metal Studs Steel Roll further solidifies [Company Name]'s commitment to advancing the construction industry through cutting-edge solutions that meet the evolving needs of the market.In conclusion, the debut of Drywall U Channel and Metal Studs Steel Roll by [Company Name] marks a significant advancement in the construction industry. These innovative building materials offer superior strength, stability, and efficiency, making them a game-changer for construction professionals and homeowners alike. With their sustainable properties and ease of installation, Drywall U Channel and Metal Studs Steel Roll are poised to transform the way buildings are constructed, setting a new standard for quality and performance in the industry.

High-Quality Steel Frame C U Cold Roll Forming Machine for sale

Steel Frame C U Cold Roll Forming Machine Revolutionizing the Construction IndustryIn recent years, the construction industry has seen a significant evolution in terms of technology and machinery. One such innovation that has revolutionized the industry is the Steel Frame C U Cold Roll Forming Machine. This cutting-edge machine has changed the way steel frames are manufactured, making the process more efficient, cost-effective, and environmentally friendly.The Steel Frame C U Cold Roll Forming Machine, developed by (), is designed to produce high-quality steel frames for various construction applications. The machine utilizes cold roll forming technology, which is a continuous and highly efficient process for shaping metal into desired profiles. This innovative technology allows for the production of steel frames with precise dimensions and strong structural integrity.One of the key features of the Steel Frame C U Cold Roll Forming Machine is its ability to produce C and U profiles with great speed and accuracy. The machine is equipped with state-of-the-art components, including a robust frame, precision rollers, and advanced control systems, ensuring smooth and seamless production of steel frames. Additionally, the machine can handle various types of steel materials, including galvanized steel, stainless steel, and carbon steel, making it versatile for different construction requirements.The introduction of this advanced cold roll forming machine has significantly improved the efficiency of steel frame production. By automating the manufacturing process, the machine can produce a large volume of steel frames in a shorter amount of time, thereby reducing production costs and labor requirements. This has made steel frames more accessible and cost-effective for construction companies, ultimately contributing to the overall growth of the construction industry.Moreover, the Steel Frame C U Cold Roll Forming Machine is also environmentally friendly. With its precise material utilization and minimal waste generation, the machine helps reduce the environmental impact of steel frame production. The use of cold roll forming technology also eliminates the need for heat treatment, further reducing energy consumption and emissions during the manufacturing process.(). The company has been a leading manufacturer of roll forming machines for over two decades, specializing in custom-designed solutions for various industries. With a strong focus on innovation and quality, the company has earned a reputation for delivering reliable and high-performance machinery to its clients worldwide.The Steel Frame C U Cold Roll Forming Machine is one of the company's flagship products, representing its commitment to providing cutting-edge solutions for the construction industry. The machine is the result of extensive research and development, incorporating the latest technological advancements to meet the evolving needs of the construction sector. With a team of skilled engineers and technicians, the company ensures that each machine is built to the highest standards of quality and performance.The impact of the Steel Frame C U Cold Roll Forming Machine in the construction industry has been profound. Its ability to streamline steel frame production, reduce costs, and minimize environmental footprint has made it a game-changer for construction companies around the world. By investing in this innovative machine, construction firms have gained a competitive edge in delivering high-quality and sustainable building solutions to their clients.As the construction industry continues to embrace technological advancements, the Steel Frame C U Cold Roll Forming Machine stands out as a prime example of how innovation can drive progress and efficiency. With its remarkable capabilities and benefits, this machine has set a new standard for steel frame manufacturing, shaping the future of construction in a more sustainable and cost-effective manner.

Roll Forming Machine for C Purlins: A Complete Guide

[Title: Industry-Leading C Purlin Roll Forming Machine Revolutionizes Construction Sector][Subheading: Streamlining Efficiency and Precision in Construction: Introduction to the C Purlin Roll Forming Machine][date][City, State] - The construction industry is on the verge of a major revolution with the introduction of the innovative C Purlin Roll Forming Machine. Developed by a pioneering industry leader [], this revolutionary machine promises to streamline efficiency and precision in the construction sector. With its advanced features and cutting-edge technology, the [brand name removed] C Purlin Roll Forming Machine is set to transform the way C purlins are manufactured, bringing unprecedented benefits to construction companies worldwide.[Paragraph 1: Introducing the C Purlin Roll Forming Machine]The newest addition to the construction industry's arsenal, the C Purlin Roll Forming Machine [], is set to redefine the manufacturing process of C purlins. A significant upgrade from the traditional manufacturing methods, this machine offers automated functionality, resulting in faster production times, enhanced precision, and reduced labor costs. By utilizing advanced roll forming techniques, the C Purlin Roll Forming Machine ensures standardized shapes and sizes, increasing the structural integrity of the final products.[Paragraph 2: Features and Capabilities]Equipped with state-of-the-art technology, the C Purlin Roll Forming Machine boasts an array of features that distinguish it as an industry leader. One of its key capabilities is its ability to produce C purlins of various sizes and thicknesses, catering to the diverse needs of construction projects. With adjustable settings and customizable parameters, construction companies can achieve unparalleled flexibility when manufacturing C purlins using this machine.Additionally, the C Purlin Roll Forming Machine incorporates automated measurement systems that guarantee accuracy and consistency in every production run. The precision positioning technology ensures that each C purlin meets the required specifications and tolerances, eliminating the risk of dimensional errors and enhancing overall construction quality.[Paragraph 3: Benefits for Construction Companies]The introduction of the C Purlin Roll Forming Machine not only revolutionizes the manufacturing process but also offers significant benefits to construction companies. With its unbeatable speed and efficiency, this machine maximizes productivity by significantly reducing production time compared to traditional methods. As a result, construction projects can be completed more swiftly, allowing for greater profitability and customer satisfaction.Furthermore, the C Purlin Roll Forming Machine eliminates the need for excessive manual labor. With its automated functionality, this machine requires minimal manpower, reducing labor costs and freeing up resources to be allocated to other crucial aspects of construction projects. This translates to substantial cost savings for construction companies, enabling them to remain competitive in a highly dynamic industry.[Paragraph 4: Environmental Impact and Sustainability]In addition to its operational advantages, the C Purlin Roll Forming Machine aligns with the growing focus on environmental sustainability. By minimizing material wastage and reducing energy consumption, this machine supports a greener approach to construction. Moreover, the standardized shapes and sizes produced by the machine promote efficient resource utilization during the construction process, minimizing waste during installation and assembly.[Paragraph 5: Market Outlook and Conclusion]With its unparalleled capabilities and wide-ranging benefits, the C Purlin Roll Forming Machine is expected to witness a soaring demand in the construction industry. Its ability to streamline efficiency, enhance precision, and reduce costs positions it as an invaluable asset for both established construction companies and emerging players. By harnessing the power of advanced roll forming technology, construction businesses can now elevate their operations to new heights, making the C Purlin Roll Forming Machine an industry-leading solution transforming the construction sector forever.In conclusion, the revolutionary C Purlin Roll Forming Machine is set to reshape the construction industry by optimizing efficiency and precision. Its advanced features, automated functionality, and sustainability focus position it as a game-changer for construction companies worldwide. As the demand for greater productivity and cost reduction rises, the C Purlin Roll Forming Machine emerges as an indispensable companion for construction businesses striving for success in the ever-evolving landscape of the construction sector.

Cold Rolled U Shape Steel Profile Manufacturer Redefines Industry Standards

Manufacturer Cold Rolled U Shape Steel Profile Offers High-Quality ProductsIn the world of construction and manufacturing, steel is an essential material that is used to build a wide range of structures and products. When it comes to steel profiles, there are a number of options available on the market, but one company that stands out for its high-quality products is **manufacturer cold rolled U shape steel profile**.**Manufacturer Cold Rolled U Shape Steel Profile** is a leading producer of cold rolled steel profiles that are used in various industries including construction, automotive, and engineering. The company is known for its commitment to producing top-quality products that meet the highest industry standards.One of the key products offered by **Manufacturer Cold Rolled U Shape Steel Profile** is its U shape steel profiles. These profiles are made using a cold rolling process, which ensures that the steel maintains its strength and durability while also being highly resistant to corrosion. This makes them an ideal choice for a wide range of applications including framing, support beams, and structural components.One of the main advantages of **Manufacturer Cold Rolled U Shape Steel Profile**'s U shape steel profiles is their versatility. These profiles can be used in a variety of applications and can be customized to meet the specific needs of each project. This makes them an ideal choice for manufacturers and construction companies who are looking for a reliable and flexible material that can be used in a wide range of applications.In addition to their versatility, **Manufacturer Cold Rolled U Shape Steel Profile**'s U shape steel profiles are also known for their high-quality finish. The cold rolling process ensures that the steel has a smooth and uniform surface, which not only looks great but also makes it easier to work with. This attention to detail is one of the reasons why **Manufacturer Cold Rolled U Shape Steel Profile** has become a trusted name in the industry.Another reason why **Manufacturer Cold Rolled U Shape Steel Profile**'s products are so highly regarded is the company's commitment to quality. The company has invested heavily in state-of-the-art manufacturing facilities and employs a team of experienced engineers and technicians who oversee the production process to ensure that every product meets the highest standards. This commitment to quality is reflected in the company's certifications and accreditations, which include ISO 9001 and CE.In addition to producing high-quality products, **Manufacturer Cold Rolled U Shape Steel Profile** also prides itself on providing exceptional customer service. The company works closely with its clients to understand their specific needs and requirements, and offers expert advice and support to help them find the right solution for their project. This personalized approach has helped **Manufacturer Cold Rolled U Shape Steel Profile** build strong and lasting relationships with its clients, many of whom are repeat customers.Looking ahead, **Manufacturer Cold Rolled U Shape Steel Profile** is committed to continuing its tradition of excellence and innovation. The company is constantly investing in research and development to find new and improved ways to produce its steel profiles, and is always looking for ways to expand its product range to meet the evolving needs of its customers.In conclusion, **Manufacturer Cold Rolled U Shape Steel Profile** is a company that is dedicated to producing high-quality steel profiles that meet the highest industry standards. With its commitment to quality, versatility, and exceptional customer service, it is no surprise that the company has become a trusted name in the industry. Whether you are a construction company, manufacturer, or engineer, **Manufacturer Cold Rolled U Shape Steel Profile** is a name that you can trust for all your steel profile needs.

Durable and Efficient Light Steel Homes: A Cost-Effective Housing Solution

Light Steel Homes Becoming a Leading Option for Sustainable and Affordable Housing SolutionsThe demand for sustainable and affordable housing options is on the rise, and light steel homes are emerging as a leading solution to meet this demand. These homes offer a range of benefits, including durability, energy efficiency, and cost-effectiveness. With the increasing focus on sustainable building practices, light steel homes are becoming a popular choice for homeowners and developers alike.The concept of light steel homes revolves around the use of steel frames for construction. The steel frames are lightweight yet incredibly strong, making them an ideal choice for building structures. In addition, steel is a recyclable material, making light steel homes an environmentally friendly option.One company leading the way in light steel home construction is {}. With a strong focus on innovation, sustainability, and quality, {} has established itself as a pioneer in the field of light steel construction. Through its advanced manufacturing techniques and cutting-edge design capabilities, the company is able to create high-quality, customizable homes that meet the needs of modern homeowners.{}'s light steel homes are designed to be energy-efficient, reducing the environmental impact of the construction process and lowering ongoing energy costs for homeowners. In addition, the company's commitment to sustainability extends to its sourcing of materials, ensuring that all components used in its homes meet rigorous environmental standards.One of the key advantages of light steel homes is their durability. Steel frames are resistant to a range of environmental factors, including fire, termites, and extreme weather conditions. As a result, light steel homes have a longer lifespan than traditional construction materials, reducing the need for maintenance and repairs over time.Furthermore, the construction process for light steel homes is faster and more efficient compared to traditional building methods. The use of prefabricated steel components allows for rapid assembly on-site, reducing labor costs and shortening the overall construction timeline. This makes light steel homes an attractive option for developers looking to complete projects more quickly and efficiently.In terms of cost-effectiveness, light steel homes offer significant advantages over conventional construction materials. The durability and low maintenance requirements of steel frames translate to long-term savings for homeowners. Additionally, the energy-efficient design of these homes can lead to lower utility bills, making them an affordable option for those looking to reduce their long-term housing expenses.Beyond the practical benefits, light steel homes also offer a high level of design flexibility. With the ability to customize the layout, size, and appearance of the home, homeowners can create a living space that meets their specific needs and preferences. This level of adaptability sets light steel homes apart from traditional housing options, providing a modern and innovative approach to home construction.As the demand for sustainable and affordable housing continues to grow, light steel homes are poised to become an increasingly popular choice for homeowners and developers. With their numerous advantages in terms of durability, energy efficiency, and cost-effectiveness, these homes represent a compelling solution for those seeking high-quality, environmentally friendly housing options.{}'s dedication to pushing the boundaries of light steel construction has positioned the company as a leader in the industry. With its commitment to innovation and sustainability, {} is helping to shape the future of housing by offering a superior alternative to traditional construction methods. As the popularity of light steel homes continues to rise, it is clear that they have the potential to transform the way we approach residential construction, providing a sustainable and affordable housing solution for communities around the world.

High-Quality Roll Forming Machine for Light Keel Production

Light Keel Roll Forming Machine is a modern type of machine that is used in the construction industry. It is used for the manufacturing of various types of light keel roll forming products, which are extensively used in the construction of lightweight steel structures. This machine is an essential tool in the construction industry and plays a significant role in producing high-quality light keel roll forming products.The Light Keel Roll Forming Machine has become a popular choice among construction companies due to its efficiency and reliability. It is designed to produce light keel roll forming products with precision and accuracy, ensuring high-quality outputs. The machine is easy to operate and requires minimal maintenance, making it a cost-effective solution for construction companies.One of the leading companies in the manufacturing of Light Keel Roll Forming Machines is {}. The company has been in the industry for many years and has established a strong reputation for producing high-quality roll forming machines. They are known for their innovative approach to machine design and engineering, and their machines are widely used in the construction industry.The company's Light Keel Roll Forming Machine is a state-of-the-art piece of equipment that is designed to meet the needs of modern construction projects. It is capable of producing a wide range of light keel roll forming products, including studs, tracks, furring channels, and various other profiles. The machine is equipped with advanced features and technology, allowing for efficient and precise production of light keel roll forming products.One of the key advantages of the company's Light Keel Roll Forming Machine is its versatility. It can produce light keel roll forming products of various sizes and shapes, making it suitable for a wide range of construction projects. The machine's flexibility and adaptability make it an ideal choice for construction companies looking to streamline their production processes and meet the demands of their projects.In addition to its versatility, the company's Light Keel Roll Forming Machine is also known for its durability and reliability. It is built to withstand the rigors of heavy-duty use in the construction industry, ensuring long-term performance and productivity. The machine is also designed to require minimal maintenance, further enhancing its reliability and cost-effectiveness.The company takes pride in its commitment to quality and customer satisfaction. They ensure that each Light Keel Roll Forming Machine undergoes rigorous testing and quality control measures to guarantee its performance and reliability. The company also provides comprehensive support and after-sales service to ensure that their customers get the most out of their machines.As the construction industry continues to evolve, the demand for high-quality light keel roll forming products is expected to increase. With the company's innovative and reliable Light Keel Roll Forming Machine, construction companies can meet these demands and stay ahead of the competition. The machine's advanced features and capabilities make it a valuable asset for any construction project, allowing for efficient and cost-effective production of light keel roll forming products.In conclusion, the company's Light Keel Roll Forming Machine is a leading solution for construction companies looking to enhance their production capabilities. With its advanced technology, versatility, and reliability, the machine is a valuable asset in the modern construction industry. As the company continues to innovate and expand its product offerings, it is poised to remain a top choice for construction companies seeking high-quality roll forming machines.

High-quality Metal Roof Tile Making Machine for Sale

Introducing a Revolutionary Stone Coated Metal Roof Tile Making MachineThe manufacturing industry is constantly evolving, with new technologies and innovations driving the market forward. One such innovation that has been making waves in the industry is the Stone Coated Metal Roof Tile Making Machine developed by a leading machinery manufacturer. This cutting-edge machine has been designed to revolutionize the production process of stone-coated metal roof tiles, offering a more efficient and cost-effective solution for manufacturers.The Stone Coated Metal Roof Tile Making Machine is a state-of-the-art piece of equipment that has been engineered to streamline the production of high-quality roof tiles. It is capable of producing a wide range of tile designs and sizes, allowing manufacturers to meet the diverse needs of their customers. The machine is also highly versatile, accommodating various materials and thicknesses, giving manufacturers the flexibility to adapt to different project requirements.One of the key features of the Stone Coated Metal Roof Tile Making Machine is its advanced automation technology. This allows for precise and consistent tile production, minimizing the margin for error and ensuring top-notch quality in every tile. The machine also boasts a high production capacity, significantly increasing output and reducing lead times for manufacturers. This not only improves efficiency but also allows manufacturers to meet the growing demand for stone-coated metal roof tiles in a timely manner.Another notable advantage of this innovative machine is its cost-effectiveness. By streamlining the production process and increasing output, manufacturers can reduce their operational costs and improve their overall profitability. The machine also requires minimal maintenance, further contributing to cost savings in the long run. Additionally, the high-quality output of the machine can enhance the reputation of manufacturers, helping them attract more customers and secure lucrative contracts.Furthermore, the Stone Coated Metal Roof Tile Making Machine is designed with sustainability in mind. It utilizes energy-efficient technologies and minimizes material waste, making it an environmentally friendly choice for manufacturers. This aligns with the growing emphasis on sustainability in the construction industry and can be a valuable selling point for manufacturers looking to appeal to eco-conscious customers.In addition to the impressive capabilities of the Stone Coated Metal Roof Tile Making Machine, the company behind this groundbreaking innovation has a strong track record of excellence in the industry. With years of experience in machinery manufacturing, they have gained a reputation for delivering high-quality and reliable solutions for their clients. Their commitment to innovation and customer satisfaction sets them apart as a leading player in the market, and their Stone Coated Metal Roof Tile Making Machine is a testament to their expertise and dedication to advancing the industry.In conclusion, the Stone Coated Metal Roof Tile Making Machine is a game-changer for manufacturers in the roofing industry. With its advanced technology, high efficiency, and cost-effectiveness, this innovative machine offers a competitive edge for manufacturers looking to stay ahead in the market. Backed by a reputable and experienced company, it is poised to transform the production process of stone-coated metal roof tiles and set new standards for quality and performance in the industry.

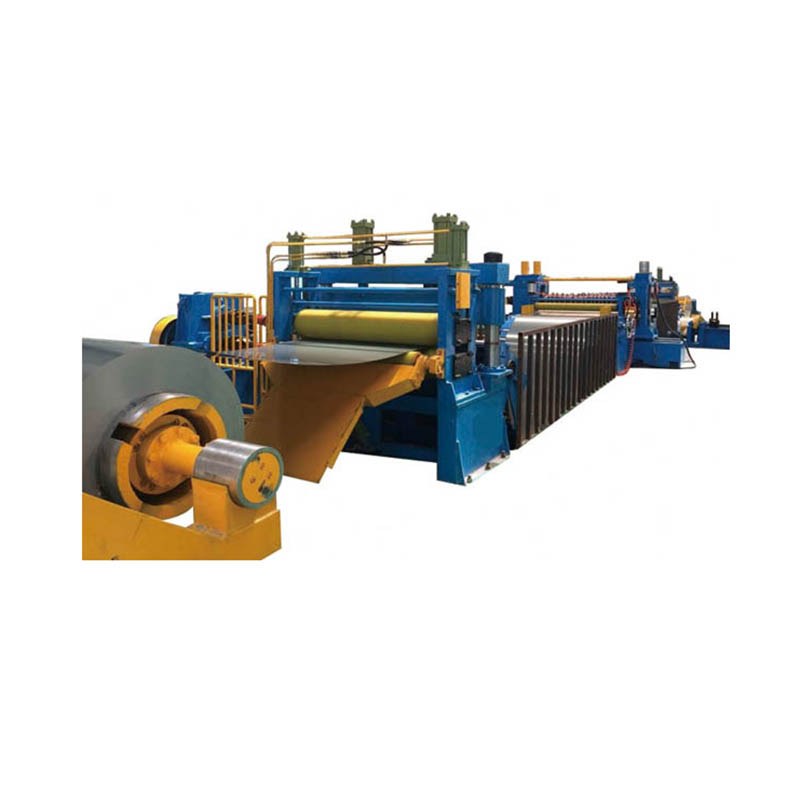

High-Quality Roll Forming Equipment for Your Manufacturing Needs

Roll Forming Equipment, a leading provider of innovative manufacturing solutions, has recently announced the launch of their latest state-of-the-art roll forming equipment. This new equipment is set to revolutionize the manufacturing industry with its advanced technology and cutting-edge features.With over 30 years of experience in the industry, Roll Forming Equipment has earned a reputation for delivering high-quality and efficient solutions for a wide range of manufacturing needs. The company prides itself on its ability to constantly innovate and stay ahead of the curve in order to meet the evolving demands of the industry.The new roll forming equipment boasts a range of impressive features that are set to streamline the manufacturing process and improve overall productivity. With its advanced automation capabilities, the equipment can significantly reduce the need for manual labor, thus increasing efficiency and reducing production costs. Additionally, its precision engineering and high-speed capabilities ensure that products are manufactured with the highest level of accuracy and consistency.Furthermore, the equipment is designed to be versatile and adaptable, allowing for the production of a wide variety of products across different industries. Whether it's for the automotive, construction, or electrical industry, this new equipment is capable of meeting the unique manufacturing needs of each sector.In addition to its advanced technological features, Roll Forming Equipment has also placed a strong emphasis on the equipment's safety and reliability. With built-in safety measures and rigorous testing procedures, customers can have peace of mind knowing that they are investing in equipment that is not only efficient but also safe to operate.To complement the launch of the new equipment, Roll Forming Equipment has also expanded its customer support services, offering comprehensive training and ongoing technical assistance to ensure that customers get the most out of their investment. Furthermore, the company’s team of experts is on hand to provide consultation and advice on how to optimize the equipment for specific manufacturing needs.With a strong commitment to innovation and customer satisfaction, Roll Forming Equipment is set to continue leading the way in the manufacturing industry. The launch of this new roll forming equipment marks yet another milestone in the company's history of providing cutting-edge solutions for manufacturers worldwide.As a company that prides itself on providing top-quality equipment and exceptional customer service, Roll Forming Equipment has quickly established itself as a trusted partner for businesses looking to improve their manufacturing capabilities. With this latest launch, the company reaffirms its commitment to delivering solutions that are not only efficient and reliable but also tailored to meet the unique needs of its customers.For more information about Roll Forming Equipment and its extensive range of manufacturing solutions, visit their website {} or contact their team directly. With a proven track record of delivering innovative and high-quality equipment, Roll Forming Equipment is poised to continue leading the way in the manufacturing industry for years to come.

High-Quality Glazed Tile Roll Forming Machine for Efficient Production

The demand for glazed tile roll forming machines has been on the rise in recent years due to the increasing construction and infrastructure development projects across the globe. To meet this demand, {Company Name}, a leading manufacturer of roll forming machines, has introduced its latest product, the 1000 Glazed Tile Roll Forming Machine.This new machine is designed to provide efficient and high-quality production of glazed tiles, which are commonly used in roofing and wall cladding applications. The 1000 Glazed Tile Roll Forming Machine is equipped with state-of-the-art technology and features, ensuring precision and accuracy in the manufacturing process.{Company Name} is known for its expertise in developing innovative roll forming solutions that cater to the specific requirements of its customers. With over {number} years of experience in the industry, the company has built a reputation for delivering reliable and high-performance machines.The 1000 Glazed Tile Roll Forming Machine is a testament to {Company Name}'s commitment to delivering cutting-edge solutions to its clients. The machine is capable of producing glazed tiles with a width of {number}mm and a thickness of {number}mm. Its high-speed production capabilities ensure a rapid turnaround time, making it an ideal choice for manufacturers looking to boost their production capacity.One of the key highlights of the 1000 Glazed Tile Roll Forming Machine is its user-friendly interface, which allows for easy operation and control. This makes it suitable for both experienced operators and those new to the roll forming process. Additionally, the machine is designed for minimal maintenance, reducing downtime and ensuring continuous production flow.In addition to its technical capabilities, {Company Name} also offers comprehensive support services to its clients. This includes installation, training, and after-sales assistance to ensure that customers can fully maximize the potential of the 1000 Glazed Tile Roll Forming Machine. The company's team of experts is committed to providing personalized guidance and assistance to clients, ensuring a seamless and efficient integration of the machine into their manufacturing operations.The introduction of the 1000 Glazed Tile Roll Forming Machine is a reflection of {Company Name}'s dedication to innovation and customer satisfaction. By constantly pushing the boundaries of roll forming technology, the company aims to empower manufacturers with the tools they need to stay ahead in a competitive market.With its advanced features and robust performance, the 1000 Glazed Tile Roll Forming Machine is set to make a significant impact in the roll forming industry. It is poised to become a go-to solution for manufacturers looking to enhance their production capabilities and deliver superior quality glazed tiles to their clients.In conclusion, the launch of the 1000 Glazed Tile Roll Forming Machine from {Company Name} represents a significant milestone in the roll forming industry. With its cutting-edge technology, user-friendly design, and comprehensive support services, the machine is set to revolutionize the production of glazed tiles and empower manufacturers to meet the growing demand in the construction and infrastructure sectors. As {Company Name} continues to lead the way in roll forming innovation, the 1000 Glazed Tile Roll Forming Machine stands as a testament to the company's commitment to excellence and customer satisfaction.